|

|

|

Commins AutoTight® Rod Holdown System |

|

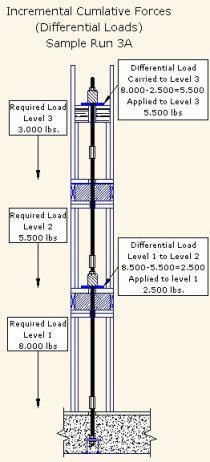

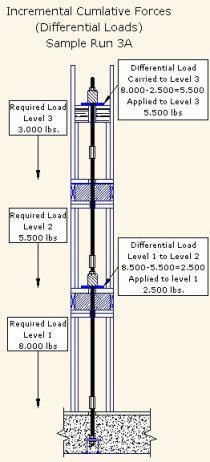

Calculate the Differential Loads:

Calculate the Differential Load (incremental uplift force). The

differential load is the difference between the uplift load at each

level vs. the level above. This load transfer point is where the

uplift load is transferred into the structure. This may happen on

every level or may skip levels.

(Note: if a load transfer point is used on every level, fewer

trimmers will be used and plate sizes can be smaller. However, more

take-up devices and plates will be needed. If floors are skipped

then fewer take-up devices are required but rod size and trimmers

may be increased.) |

|

Sample: Run 3A uses R6 rod (3/4”) on level 1 and R5

rod (5/8”) on levels 2 and 3. Take-Up devices are always installed

at levels where the threaded rod size changes.

1. In sample Run 3A, the differential load transfer will occur at

level 1 and level 3.

2. The differential load at level 1 is the difference between level

1and 2. (8,000-5,500 = 2,500 lbs.)

3. The differential load at level 3 is the remaining run load.

(8,000 – 2,500 = 5,500 lbs.)

Note: Load transfer points are always on the floor of the story

above. Loads are carried through the floor and into the story below.

(Exception: when a header is used with short trimmers in a wall,

usually at the top floor)

After the differential load information is put into the table the

balance of the runs can be determined. |

|

|

|

|

|

Sample Load Justification (Table B) |

|

|

|

|

|

|

3A |

|

|

4A |

|

|

5A |

|

|

|

|

|

Reqd |

Tension |

Diff. |

Reqd |

Tension |

Diff. |

Reqd |

Tension |

Diff. |

Story |

Estimated |

|

Level |

Load |

Load |

Load |

Load |

Load |

Load |

Load |

Load |

Load |

Heights |

Wood |

|

|

lbs |

Rod |

Plate |

lbs |

Rod |

Plate |

lbs |

Rod |

Plate |

|

Shrinkage |

|

5 |

|

|

|

|

|

|

3,500 |

6,136 |

6,000 |

10" - 0" |

0.25" |

|

|

|

|

|

|

|

|

|

R5 |

|

|

|

|

4 |

|

|

|

3,500 |

6,136 |

6,000 |

6,000 |

6,136 |

|

10' - 0" |

0.25" |

|

|

|

|

|

|

R5 |

|

|

R5 |

|

|

|

|

3 |

3,000 |

6,136 |

5,500 |

6,000 |

6,136 |

|

10,000 |

15,708 |

9,500 |

10" - 0" |

0.25" |

|

|

|

R5 |

|

|

R5 |

|

|

R8 |

|

|

|

|

2 |

5,500 |

6,136 |

|

11,000 |

15,708 |

9,500 |

15,500 |

15,708 |

|

10' - 0" |

0.25" |

|

|

|

R5 |

|

|

R8 |

|

|

R8 |

|

|

|

|

1 |

8,000 |

8,836 |

2,500 |

15,500 |

15,708 |

|

24,500 |

24,544 |

9,000 |

10" - 0" |

0.25" |

|

|

|

R6 |

|

|

R8 |

|

|

R10 |

|

|

|

|

<< Back

Next>>

Key Structural Information

Organizing the Runs

Specifying the Rod Size

Specifying the AutoTight® Components |

Download -

Specifying

the AutoTight® System . pdf - (4

pages, 111.1k)Acrobat Reader is required to view the

material.

|

|

|

Contact

Webmaster with questions

or comments |

Copyright 2005

Commins Manufacturing, Inc., Friday Harbor, WA 98250, Tel (360) 378-9484 |

| |

AutoTight® Rod Holdown

Systems and components are covered by one or more of the following U.S.

Patents 6,390,747; 6,585,469; 6,625,945, other patents both foreign and

domestic are pending. |

|