|

Installation Guide - Rod System |

|

Rod System Install

AT Device Install |

|

Header Install

Trimmer Install |

Embedment Install

Beam Start Install |

The installation procedures described are

recommendations, based on our experience and input from field

installers. Every project is a little bit different and we encourage

additional input to continually improve our system's installation.

Always consult the AutoTight® supplied plans for the correct

materials, information and details for the runs to be installed.

|

|

|

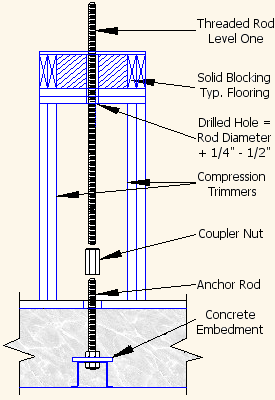

• Install the first level Shearwall over the

Embedment Anchor Rod.

•

Drill a hole 1/4" - 1/2" larger than the diameter of the threaded rod to be

installed. The hole is to be located directly above the anchor bolt.

•

Use the AutoTight®

stud layout drawing or a plumb bob to locate the

hole position. The rod may be offset a maximum of 2" per 10' floor

height, if required. |

Recommended Tools

1/2" Right Angle Drill, 17" Ship Auger

and 18" Bit Extension

Crescent Wrench, Channel Locks

and Phillips Screwdriver |

|

• Install the proper size and length first level

rod for the run by feeding it down through the previously drilled

hole from the level above.

•

Install the proper coupler nut approximately halfway onto the anchor

rod.

•

Thread the rod into the coupler nut insuring that the threaded rod

is fully seated at the midpoint of the coupler.

|

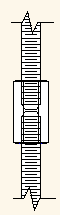

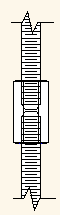

Coupler with

Threaded Rod

Fully Seat at

Mid-Point

of the Coupler |

|

|

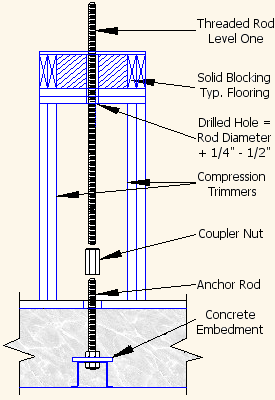

• Drill the bottom plate for the next level Shearwall to match the rod diameter from the level below. Locate the

position of the hole using the stud layout per the plans or matching

the lower level layout.

•

After placing the Shearwall in place, drill a

hole into the top plate a 1/4" - 1/2" larger than the diameter of the threaded rod for the

level. The hole maybe smaller to match the rod for the level.

•

The hole is to be located directly above the installed rod

centerline from the lower level. The rod may be offset a maximum of 2" per 10'

floor height, if required. |

•

Install the Bearing Plate, AT Device, Washer and Nut, if required on

the Bottom Plate of the Shearwall. AT

Device Installation

•

Install the Coupler Nut or Reducer Coupler Nut as required.

•

Repeat the level install process for the next level. |

|

Rod System Install

AT Device Install |

|

Header Install

Trimmer Install |

Embedment Install

Beam Start Install |