| AutoTight® |

by

Commins Manufacturing, Inc. |

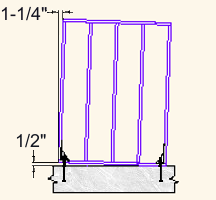

| The Continuous Rod Holdown System |

|

AutoTight® AT Take-Up Device |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

All AT Take-Up Devices Tested to ICC-ES

AC316 |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Testing: |

The AT was tested to 104,683 pounds at failure and is load rated to 34,500 lbs. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Code Acceptance: |

ICC ES ER-5889 per AC316; COLA RR 25480 |

Material: |

Alloy Steel |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Finish: |

Yellow zinc chromate, moly di-sulfide dry lubricant. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: |

The Commins AutoTight® Rod Holdown Systems, holdowns etc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Installation | Set-Nut-Activate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. |

Allow 4” of anchor bolt to project through the steel plate or holdown. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. |

Drop the AT device into the holdown - Arrow up. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3. |

Place a steel washer on the AT (No lock washers!). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4. | Install and tighten a nut on the AT. Tighten. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5. | Activate. Remove and discard the activation screw. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The AT Auto Take-Up installs up to 10 times faster than the competition. Nothing installs faster! | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

US Patents 6,390,747 6,585,469

Other patents, foreign and domestic, pending

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Notes: AT may be stacked, Install per directions, keep clean and dry. Loads based on FS=3 on lowest of three tests. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Download - AutoTight® AT Product Description . pdf - (1 pages, 214k) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Conversions | How to Specify | Installation Guide | Standard Systems | Contact Us |

Contact Webmaster with questions or comments

Copyright 2005 Commins Manufacturing, Inc., Friday Harbor, WA 98250, Tel (360) 378-9484

AutoTight® Rod Holdown Systems and components are covered by one or more of the following U.S. Patents 6,390,747; 6,585,469; 6,625,945, other patents both foreign and domestic are pending.